Packaging & Merchandising Design - Project 1

14.05.2024

1. Clip (fig 1.3):

The clip set is currently packaged in a plastic bag, which offers minimal protection and is not reusable. Clips are small, lightweight items that are often misplaced or scattered when not stored properly. Designing a custom reusable box for the clips would significantly enhance their functionality by providing organized storage even after purchase. The custom box can have compartments or sections, allowing users to conveniently keep their clips sorted and easily accessible. This not only improves presentation on the shelf but also adds long-term value for the consumer.

2. Brush Set (fig 1.4):

The brush set is packaged in a blister card, which is not ideal for long-term storage and lacks protection once opened. These brushes are tools that require careful handling to maintain their shape and cleanliness. A custom reusable box will allow users to store the brushes safely after use, preventing damage to the bristles and keeping the brushes clean and dust-free. The new packaging would offer a more premium feel, improve user convenience, and extend the lifespan of the product, making it more appealing to customers.

Digitalization

Laser Cut Result (Failed Attempt)

This are the failed attempt where the line are not scored properly. So with the help of a hammer, then the line become better. Here is the final Brush Box :

Graciella Limpah / 0364517

Packaging & Merchandising Design / Bachelor of Design (Honours) in

Creative Media / Taylors University

Project 1

JUMPLINK

INSTRUCTIONS

Exercise - Packaging Product Analysis

Practice in Class

For in class practice, we have to make a packaging for a massage ball. I find

inspiration from pinterest and then I found the packaging I like and I try to

draw the guideline and cut it. Here is the result :

|

| fig 1.1 Box for massage ball |

|

| fig 1.2 Dieline for massage ball |

Next, in week 4, we have to bring 2 non-box products to make a box for the

products. I choose a shirt clip and a brush. Here is the products :

|

| fig 1.3 Clip |

|

| fig 1.4 Brush |

1. Clip (fig 1.3):

The clip set is currently packaged in a plastic bag, which offers minimal protection and is not reusable. Clips are small, lightweight items that are often misplaced or scattered when not stored properly. Designing a custom reusable box for the clips would significantly enhance their functionality by providing organized storage even after purchase. The custom box can have compartments or sections, allowing users to conveniently keep their clips sorted and easily accessible. This not only improves presentation on the shelf but also adds long-term value for the consumer.

2. Brush Set (fig 1.4):

The brush set is packaged in a blister card, which is not ideal for long-term storage and lacks protection once opened. These brushes are tools that require careful handling to maintain their shape and cleanliness. A custom reusable box will allow users to store the brushes safely after use, preventing damage to the bristles and keeping the brushes clean and dust-free. The new packaging would offer a more premium feel, improve user convenience, and extend the lifespan of the product, making it more appealing to customers.

Then, I try to sketch out how the box will look like.

|

| fig 1.5 Sketches |

Next, I try to make prototype for each box. Here is the prototype process

:

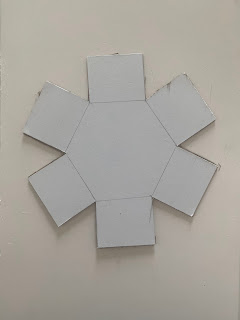

Clip Box :

|

| fig 2.1 Dieline cut for clip box |

Brush :

|

| fig 2.2 Dieline for cap of the brush box |

|

| fig 2.2 Dieline cut for cap of the brush box |

|

| fig 2.3 Dieline for box of the brush box |

|

| fig 2.4 Dieline cut for box of the brush box |

Then, here is the result (not the best, but at least I know how will it work)

:

Clip Box

|

| fig 3.1 Prototype of clip box |

|

| fig 3.2 Prototype of clip box |

|

| fig 3.3 Prototype of clip box |

Brush :

|

| fig 3.4 Prototype of brush cap box |

|

|

|

After doing the prototype for each of the item, I move to illustrator to make

the digitize version for the dieline.

Process :

fig 4.1 Process of Digitalization (left is clip, right is brush)

When doing consultation with Mr.Sham, he also showed me how to make the

dieline better.

Final Digitalization :

After consulting with Mr.Sham, he asked me to improved some part from the

digitalize version. I try to improvised and here is the finished result

:

fig 4.2 (left is brush, right is clip)

CLIP BOX

FIRST TRIAL

Laser Cut Process :

After doing the digitalization, moving on to the laser cut process.

Here is the laser cut process:

.jpeg)

|

| fig 4.3 Laser Cut Process |

|

| fig 4.4 Laser Cut Process |

For clip box, I manage to do it accordingly to what my prototype looks

like.

|

| fig 5.1 Clip Box |

|

|

|

|

| fig 5.3 Clip Box Result |

|

|

|

|

|

|

|

|

|

|

|

|

SECOND TRIAL

After receiving feedback from Mr.Sham, I need to re-do my packaging because

it looks not neat and I cannot use the tape outside the box. So, I come back

to the laser cut place and try laser cut it again. I also change the dieline

so I have parts to stick it inside (to avoid using tape)

Dieline

|

| fig 6.2 Laser Cut Process |

|

| fig 6.3 Laser Cut Process |

|

| fig 6.4 Laser Cut Process |

|

| fig 6.5 Laser Cut Process |

|

| fig 6.6 Laser Cut Process |

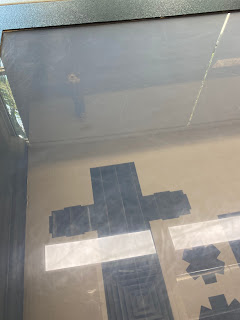

Laser Cut Result (Failed Attempt)

BRUSH BOX

First Trial

I use a thinner paper for this first trial but it didn't turn out well, I'm

also thinking of how the box will open but I don't think it can because the

lower part cannot stand, it's too thin.

|

| fig 8.1 First Trial box |

|

| fig 8.2 First Trial box |

fig 8.3 First Trial box

Second Trial

Then, I change a little bit of how the inside will look like. I also

change the material into corrugated box so it can stand.

|

| fig 9.1 Digitalization for brush box |

|

| fig 9.2 Brush box |

|

| fig 9.3 Brush box |

|

| fig 9.4 Dieline for brush box |

|

| fig 9.5 Brush box result |

|

| fig 9.6 Brush box result |

|

| fig 9.7 Brush box result |

|

| fig 9.8 Brush box result |

|

| fig 9.9 Brush box result |

Third Trial

After receiving feedback from Mr.Sham, I redo my box to make it looks nicer.

|

| fig 10.1 2 Failed Attempt |

This are the failed attempt where the line are not scored properly. So with the help of a hammer, then the line become better. Here is the final Brush Box :

|

| fig 10.2 Final Brush Box |

|

| fig 10.3 Final Brush Box |

|

| fig 10.4 Final Brush Box |

|

| fig 10.5 Final Brush Box |

|

| fig 10.6 Final Brush Box |

|

| fig 10.7 Final Brush Box |

FINAL

Paper Clip Box

Brush Box

FEEDBACK

Week 5: Proceed with the items chosen

Week 6: Need to change the material that are used from the

prototype, because it is not suitable. Need to be very precise when

doing digitalization.

REFLECTION

This task allowed me to explore a wide range of packaging designs,

starting from identifying non-boxed items to imagining how custom

packaging could enhance their form and function. It was an insightful

process that challenged me to think creatively and practically.

Although I found it difficult to make the lines and measurements

precise, I did my best to achieve accuracy and improve my skills.

Creating the prototype was especially enjoyable; it was exciting to

see my initial sketches transformed into a real, tangible box. This

hands-on experience helped me better understand the connection between

design and functionality in packaging.

Comments

Post a Comment